Tel:+86 592 6220885

Fax:+86 592 6220886

Add:No. 18 Xinling Road, Houxi Industrial Park, Jimei District, Xiamen, China

The rubber ball molding process is to put the mixed rubber into the mold, add vulcanizing agent and other ingredients, and press the rubber ball with a flat vulcanizer under the specified time, pressure and temperature conditions. The molded rubber balls go through secondary processing procedures, such as rubber deburring, secondary vulcanization, cleaning and various inspections. The product is called rubber ball molded product, or molded product for short. The main raw materials of rubber balls are raw rubber, various compounding agents and fibers as skeleton materials. The basic production process of rubber balls includes six basic processes of rubber mixing, mixing, calendering, extrusion, molding and vulcanization. The processing of rubber balls is mainly to solve the contradiction between plasticity and elasticity. Through various processing methods, elastic rubber balls are turned into plastic pellets, and various compounding agents are added to make semi-finished products, and then vulcanized into plastic semi-finished products, rubber balls and rubber products with high elasticity and good physical and mechanical properties.

After the rubber product is formed, there will be some burrs on the product. On the one hand, the burr treatment of rubber products has high requirements on the appearance of the product, on the other hand, it also has an inevitable relationship with the price of the product. Generally speaking, manufacturers have certain production costs in the process of processing raw edges of rubber products. Therefore, in the process of processing raw edges, manufacturers pay more attention to the processing efficiency of raw edges of rubber products on the premise of ensuring product quality.

The burr treatment of rubber products is often divided into the following categories: Manual trimming: high labor intensity, low efficiency, and low pass rate. Mechanical trimming: mainly includes punching, grinding wheel trimming, round knife trimming, suitable for specific products with low precision requirements. 3. Frozen edge trimming: special frozen edge trimming machine equipment, the principle is to use liquid nitrogen (ln2) to make the burr of the finished product brittle at low temperature, and use specific frozen particles to strike the burr, so as to quickly remove the burr. Freeze trimming has become the mainstream technical standard due to its high efficiency, low cost and wide product range.

Rubber deburring process:

1. Put the molded rubber ball into a special rubber burr centrifuge.

2. The rubber burr centrifuge should have a rubber ball to grind the material, and then add an appropriate amount of water.

3. During the grinding process, control the grinding time of rubber balls. Generally check the size, appearance and surface finish of the rubber ball every 30 minutes. At the same time, the amount of water in the centrifuge should not be too little or too much.

4. Check the deburred rubber ball in various aspects.

Generally, rubber products are deburred according to the shape of the product and the needs of customers, so as to make high-quality products faster and more effectively.

If you need to know more about rubber deburring, you can find us. We have detailed knowledge about rubber deburring.

————————————————————————————————————————

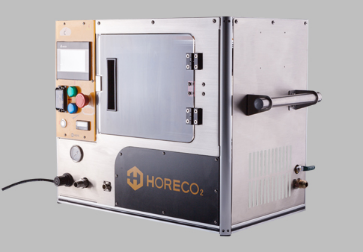

Xiamen Hefengli Dry Ice Decontamination Equipment Co., Ltd., referred to as Hefengli Dry Ice, was established in 1999. It is a professional enterprise dedicated to the application of dry ice in China. It has formed a complete industrial chain of R&D, manufacturing, sales and after-sales. The company's brand is HORECO2, and Hefengli has a doctoral-level R&D team. Its main products include Dry ice granulator & block making machine, Dry ice cleaning machine, dry ice automatic production line, dry ice intelligent cleaning, supply of dry ice of various specifications, dry ice Cleaning service and leasing, Dry ice insulation box, dry ice equipment accessories and related intelligent products; 18 dry ice manufacturing factories have been deployed to provide a complete dry ice distribution service network and provide customers with a cost-effective experience.