Tel:+86 592 6220885

Fax:+86 592 6220886

Add:No. 18 Xinling Road, Houxi Industrial Park, Jimei District, Xiamen, China

Dry ice deburring:

Dry ice deburring is the use of dry ice pellets to mechanically deburr molded parts that have become brittle through precooling. The impact effect of dry ice particles is used. The cleaning effect is determined by the speed as well as the dry ice particle size and density and the quality of the dry ice. The dry ice pellets transfer heat from the dry ice pellets to the corresponding burrs as they strike the burrs, resulting in a pronounced temperature gradient and corresponding high shear forces in the burrs, which facilitates the removal of the burrs. Finally, dry ice particles sublimate upon impact to produce gaseous CO, which occupies significantly more volume than solid dry ice particles. This explosive increase also brings a pulse to the point of impact, which helps with removal work.

Reasons to Deburr with Dry Ice

1. The dry ice deburring process uses dry ice pellets accelerated by compressed air to remove burrs and burrs from plastic and metal parts. Dry ice sublimates (turns from a solid to a gas) when it hits the surface of the part, so the cleaning process essentially eliminates the need for other media.

2. Dry ice deburring is recommended for parts with small holes or cavities, thick flash burrs, and challenging flash or warped locations. The dry ice spray process is also a good option for parts that are too large or heavy to tip over.

3. Since dry ice blasting uses individual part cleaning rather than mixed part cleaning, it provides a more immediate cleaning effect than other processes. In addition, dry ice cold spray cleaning can achieve higher compatibility, up to 140 PSI cleaning pressure regulation. High velocity dry ice media pellets can remove heavy plastic burrs, fine metal burrs and other undesirable part burrs.

4. Some parts have hard-to-reach burrs, such as deep and narrow through-holes, which need to be processed at precise angles. When the opening of the pores is narrow, the area that can be cleaned by the media-driven batch method becomes shallow. For parts with particularly challenging flash or burr locations, dry ice deburring is an effective option.

Freeze deburring:

Freezing deburring is mainly through the low-temperature freezing of liquid nitrogen to embrittle the rubber and silicone materials. After the burrs are frozen, the hardness will be better than before. After high-speed operation, a polymer projectile is ejected and hits the burrs. , After the burr is hit, the structure changes and falls down, and liquid nitrogen removes the burrs of rubber products, such as watch straps, aluminum, and zinc alloy products. The material of the rubber material is subject to temperature changes, and the material begins to harden. Under normal conditions, no deformation and damage will occur without being squeezed, and the physical and chemical properties will not change after returning to normal temperature. The method of freezing and deburring can be deburred according to the shape requirements of the product. Due to the low efficiency of traditional manual deburring, the defect rate of the product cannot be guaranteed. However, the effect of freezing and deburring with liquid nitrogen can be seen, and the defectiveness of the product can be seen. The efficiency has dropped, and some special products can be removed, products that cannot be removed manually.

————————————————————————————————————————

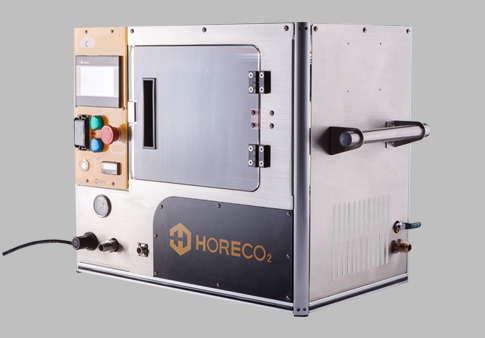

Xiamen Hefengli Dry Ice Decontamination Equipment Co., Ltd., referred to as Hefengli Dry Ice, was established in 1999. It is a professional enterprise dedicated to the application of dry ice in China. It has formed a complete industrial chain of R&D, manufacturing, sales and after-sales. The company's brand is HORECO2, and Hefengli has a doctoral-level R&D team. Its main products include Dry ice granulator & block making machine, Dry ice cleaning machine, dry ice automatic production line, dry ice intelligent cleaning, supply of dry ice of various specifications, dry ice Cleaning service and leasing, Dry ice insulation box, dry ice equipment accessories and related intelligent products; 18 dry ice manufacturing factories have been deployed to provide a complete dry ice distribution service network and provide customers with a cost-effective experience.