Tel:+86 592 6220885

Fax:+86 592 6220886

Add:No. 18 Xinling Road, Houxi Industrial Park, Jimei District, Xiamen, China

With the rapid development of industries such as automobiles, motorcycles, and aerospace, industrial casting molds have grown rapidly at a rate of more than 25% per year, and casting mold technology has made great progress. Representative large and complex die-casting molds mainly rely on imports. my country's automobile and motorcycle industries have entered a high-speed growth period, and their output has increased significantly for many years in a row. It can be predicted that in the next 10 to 20 years, the production of my country's industrial mold casting molds will still receive strong thrust mainly from the automobile industry and grow at a high speed. In the context of energy conservation and emission reduction, the increase in ferrous metal gravity casting molds will slow down, while aluminum-magnesium alloy die-casting molds, low-pressure casting molds and squeeze casting molds will increase significantly.

Dry ice cleaning mold: Dirt will be generated during the use of industrial molds. The mold is the determiner of the product shape and the key factor to ensure the internal quality of the finished product. Therefore, the mold should be cleaned frequently. The commonly used technology is dry ice mold cleaning technology.

Dry ice blasting is a brand-new cleaning technology. It is dry, non-toxic, non-abrasive, and non-secondary pollution cleaning method. Traditional sandblasting cleaning or chemical cleaning agent cleaning will damage the mold. Dry ice cleaning has no wear on the mold, and the cleaning intensity can be adjusted arbitrarily, effectively removing corners, crevices and uneven surfaces and corners. Dry ice is solid carbon dioxide. After cleaning, there is no water residue, no mold corrosion, no secondary pollutants during cleaning, energy saving and environmental protection.

The principle of Hefengli Dry ice cleaning machine is to use compressed air as the power and carrier, dry ice particles as accelerated particles, and spray them onto the surface of the object to be cleaned through a special Dry ice cleaning machine, using the momentum of high-speed moving solid dry ice particles Change, sublimation, melting and other energy conversion, so that the dirt, oil, residual impurities, etc. on the surface of the object to be cleaned are quickly frozen, so that they are condensed, embrittled, stripped, and removed with the airflow at the same time. The temperature of dry ice is minus 78.5 degrees Celsius. When the low-temperature dry ice is sprayed onto the surface of the object to be cleaned at room temperature, the volume instantly expands by nearly 800 times, causing the dirt to be cracked, fragmented, and peeled off. The dry ice cleaning process will not cause any damage to the surface of the cleaned object, especially the metal surface, nor will it affect the finish of the metal surface.

————————————————————————————————————————

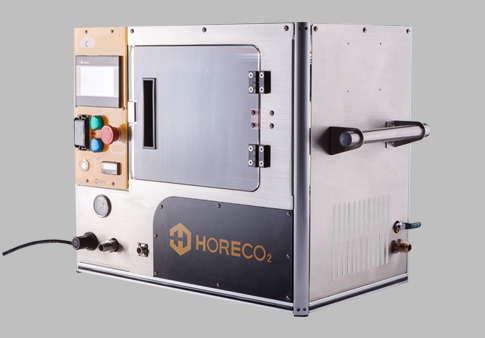

Xiamen Hefengli Dry Ice Decontamination Equipment Co., Ltd., referred to as Hefengli Dry Ice, was established in 1999. It is a professional enterprise dedicated to the application of dry ice in China. It has formed a complete industrial chain of R&D, manufacturing, sales and after-sales. The company's brand is HORECO2, and Hefengli has a doctoral-level R&D team. Its main products include Dry ice granulator & block making machine, Dry ice cleaning machine, dry ice automatic production line, dry ice intelligent cleaning, supply of dry ice of various specifications, dry ice Cleaning service and leasing, Dry ice insulation box, dry ice equipment accessories and related intelligent products; 18 dry ice manufacturing factories have been deployed to provide a complete dry ice distribution service network and provide customers with a cost-effective experience.