Tel:+86 592 6220885

Fax:+86 592 6220886

Add:No. 18 Xinling Road, Houxi Industrial Park, Jimei District, Xiamen, China

The dry ice cleaner is mainly used for rubber and plastic mold cleaning, casting mold cleaning, composite tool cleaning, composite product surface cleaning, spray pretreatment, product trimming and deburring, degreasing, degumming, mold removal agent... The dry ice particles of the dry ice cleaner will produce embrittlement explosion after contacting the dirt surface, thus causing the dirt to shrink and loosen, and then the dry ice particles will vaporize instantaneously and expand 800 times, It produces a strong peeling force, which can quickly and thoroughly remove dirt from the surface of the object, so as to achieve a fast, efficient, safe and energy-saving cleaning effect.

The dry ice cleaner can be used in that place. Of course, the demand for precision instruments should be high-end. It is no problem to use it with the Fengli dry ice cleaner. If the dry ice machine is an ordinary model for cleaning large machinery such as printing equipment, it will be OK. Our equipment cleaning range is very wide. The main purpose is cleaning. The application fields include: mold, hardware, ship, aircraft, high-speed rail, printing and other industries

What scenarios can the dry ice cleaner be used in? The dry ice cleaner actually uses the dry ice cleaner to remove the residue on the mold. The dry ice cleaner can clean the equipment when the equipment is not stopped and the mold temperature is high, which reduces the downtime for cleaning the mold. The traditional cleaning of the mold takes about 3 hours, but only 20 minutes now. The dry ice cleaner is much more convenient than the traditional cleaning in terms of time.

Because dry ice is solidified by gas carbon dioxide, and dry ice is anhydrous and non-corrosive; Therefore, the whole dry ice cleaning process is non-corrosive and abrasive, and will not wear the key tool tolerances. The micro ventilation hole solves the traditional manual drilling by using dry ice spray cleaning. In fact, the dry ice cleaner is a very good choice for cleaning the mold, because the mold and mold are usually cleaned by traditional cleaning methods under high temperature, which is easy to cause damage to the mold and poor cleaning speed, while the dry ice cleaner has greatly improved the cleaning efficiency and shortened the disassembly cleaning time.

For example, dry ice cleaning in metal stamping molds, food industry, die-casting molds and rubber molds. In most cases, the residual sugar in the food industry can also be used to replace high-pressure water guns and detergents, especially the growth of Salmonella in food, and dry ice cleaning can prevent growth; In addition, the residue of waffles and other similar dough on the conveyor belt and oven can be cleaned by dry ice cleaner. It has been found that CO 2/dry ice spray can remove and/or destroy the significant biofilm accumulation of Listeria and Salmonella. In fact, dry ice cleaning can also be used in a variety of occasions. With the rapid development of industrial production, many industrial equipment are inevitably cleaned in the production process.

The traditional cleaning method cannot solve the online cleaning problem, while the dry ice cleaner can solve this problem, such as cleaning the transportation components, removing the mechanical oil stains, and removing the rust of the equipment. The most difficult problem to solve in the printing industry is ink and solvent-resistant when cleaning the printing machine with dry ice cleaner. It is particularly troublesome to clean dry ink. The ink accumulation on the gear and platform guide rail leads to poor alignment and low print quality.

With innovative technology as the driving force, Hefengli Intelligent Dry Ice Cleaning Technology continues to develop leading technology products. The company is customer-centered and service-oriented; Pursue excellence with professional value, create industry brand model, realize value maximization, repay the society, and dedicate in good faith as the enterprise mission; Make the greatest contribution in the field of environmental protection.

———————————————————————————————————————

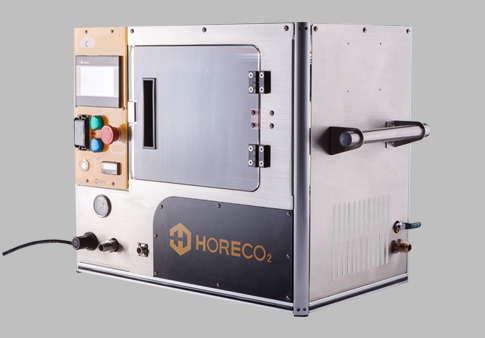

Xiamen Hefengli Dry Ice Decontamination Equipment Co., Ltd. (hereinafter referred to as Hefengli Dry Ice), founded in 1999, is a Chinese enterprise specializing in dry ice application, forming a complete industrial structure chain of R&D, manufacturing, sales and after-sales. The company's brand is HORECO2, and Fengli has a doctor-level research and development team. Its main products include dry ice granulator&briquetting machine, dry ice cleaning machine, dry ice automatic production line, dry ice intelligent cleaning, supply of various specifications of dry ice, dry ice cleaning services and leasing, dry ice insulation box, dry ice equipment accessories and related intelligent products; It has arranged 18 dry ice manufacturing plants, provided a complete dry ice distribution service network, and provided customers with a cost-effective use experience.