Tel:+86 592 6220885

Fax:+86 592 6220886

Add:No. 18 Xinling Road, Houxi Industrial Park, Jimei District, Xiamen, China

It is used in dry ice spray cleaning. Here, large dry ice particles (pellets) are sprayed onto the surface at high speed (sound speed) for cleaning. There are three physical effects:

heat energy

Temperature difference between dirt layers (cold shock - 79 ° C)

kinetic energy

Particles have low hardness (2 Mohs) at high speed and do not damage the surface.

mechanical energy

The life of particles in contact with the surface to be cleaned means that they change from solid state to gas state. The volume of the particles increased to 700 times that of them.

Particles destroy pollution and separate it without damaging the surface. The surface is free of grease.

1、 What is dry ice?

Dry ice is solid carbon dioxide (CO2), which sublimates under normal conditions at - 79 ℃, that is, directly enters the gas phase without first melting. Dry ice is prepared by decompressing carbon dioxide under pressure. Part of the carbon dioxide evaporates, thus extracting the heat required for evaporation from the rest, thus cooling it. The result is so-called frozen snow carbonate. Then press it into the desired shape according to the application.

2、 Application field

There are many fields and industries that can effectively and economically use dry ice cleaning, and many fields and industries can prove its advantages over traditional cleaning methods. Let's show you some industries and the purpose of cleaning and removal:

Production process:

Mechanical engineering, mold manufacturing, foundry, rubber engineering, rolling mill, cardboard and corrugated board production, particleboard and synthetic resin board production, fire protection, asbestos removal, chemical industry, textile industry, food industry, slaughterhouse, butcher, smoking room, commercial kitchen, garage, bus and truck maintenance, railway, aircraft manufacturing and maintenance, shipyard, painting, painting and coating equipment, electroplating, etc.

Cleaning and cleaning:

Polystyrene foam plastics, molds in plastic and rubber industries, die-casting tools, printing machines, rotary printing machines, flat waffle furnaces, engines, engines, turbines, elevators, escalators, centrifuges, conveying systems, tank and boiler systems, air conditioning and ventilation systems, wood, metal, rims, plastics, concrete, natural stone, artificial stone, bricks, exterior walls, electrical parts, plastic furniture, tents, tunnels, Bridge, ship, cheese wheel, bacon bandage, etc

Surface treatment:

Lubricating grease, oil, plastic residue, rust, soot, asbestos, crusts, slag, lime, urolith, Teflon, asphalt, PU foam, graffiti, chewing gum, pigeon feces, paint, varnish, glue, sealant, release agent, antifouling, algae, moss, etc

3、 What does the dry ice cleaning process need?

For dry ice cleaning, you need the following equipment:

Compressed air (mobile or stationary compressor)

Dry ice particles

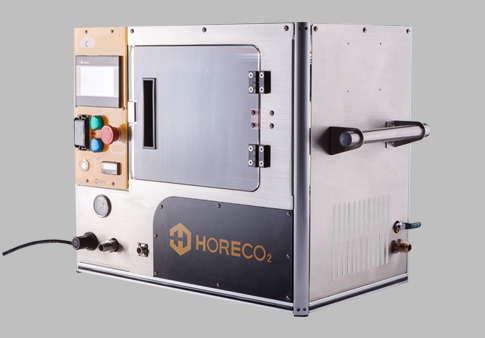

Dry ice cleaner

Occupational safety measures (hearing and face protection, gloves, etc.)

———————————————————————————————————————

Xiamen Hefengli Dry Ice Decontamination Equipment Co., Ltd. (hereinafter referred to as Hefengli Dry Ice), founded in 1999, is a Chinese enterprise specializing in dry ice application, forming a complete industrial structure chain of R&D, manufacturing, sales and after-sales. The company's brand is HORECO2, and Fengli has a doctor-level research and development team. Its main products include dry ice granulator&briquetting machine, dry ice cleaning machine, dry ice automatic production line, dry ice intelligent cleaning, supply of various specifications of dry ice, dry ice cleaning services and leasing, dry ice insulation box, dry ice equipment accessories and related intelligent products; It has arranged 18 dry ice manufacturing plants, provided a complete dry ice distribution service network, and provided customers with a cost-effective use experience.