Tel:+86 592 6220885

Fax:+86 592 6220886

Add:No. 18 Xinling Road, Houxi Industrial Park, Jimei District, Xiamen, China

Many electronic component manufacturers are usually troubled by cleaning the injection mold, because the injection mold is a key component in the production of high-quality products. Cleaning the curing agent and release agent in the mold cavity and vent holes can prevent the product from being uncleaned. question.

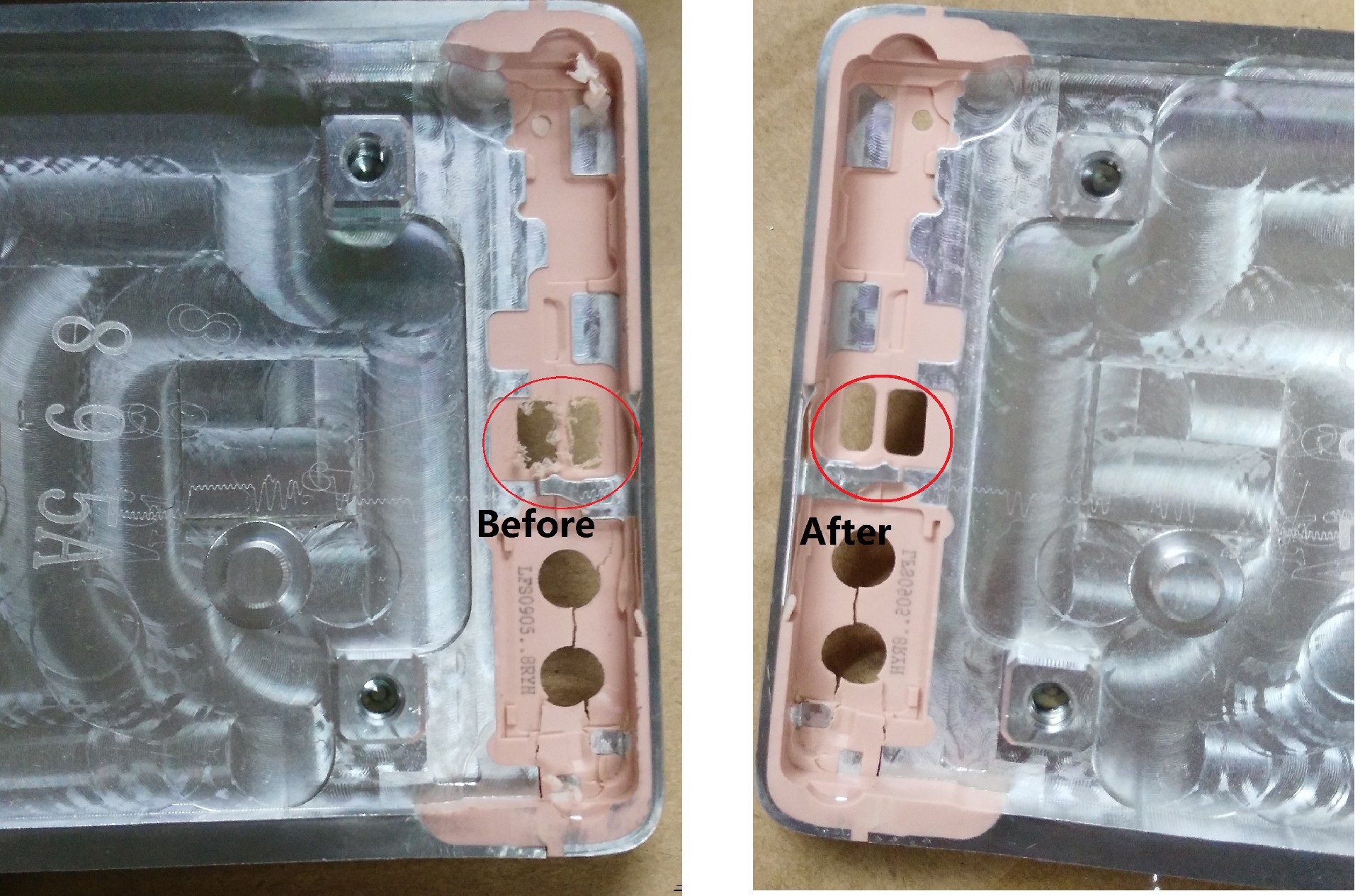

In order to ensure the quality of products, general electronic component manufacturers usually clean the mold once every 48 hours. Since the plastic accumulates on the mold during the manufacturing process, the vent of the mold will be blocked. When the vent is blocked, the gas that cannot be discharged will form Mold parts cause burn marks.

In order to quickly clean the mold, manufacturers try a variety of cleaning methods: ultrasonic cleaning, sandblasting cleaning, chemical solvents and manual cleaning. These methods can be effectively cleaned, but they also cause certain wear and tear on the mold, and are very time-consuming and laborious. Seriously, it will affect the tolerance of key parts of the mold. The most critical thing is that the mold needs to be disassembled to cause downtime and affect production.

What advantages can dry ice cleaning machine bring to electronic components cleaning?

The dry ice cleaning process is to use the strong pressure gas of the air compressor to spray dry ice particles to the surface of the object to be cleaned at high speed. Due to the physical sublimation of dry ice, the stains are peeled off from the surface, and the dry ice will directly sublimate into gas without causing secondary damage to the object. Pollution, no secondary residues, the key is that dry ice blasting can be cleaned online without stopping the machine, which saves cleaning time, improves production efficiency, reduces cleaning costs, and achieves truly environmentally friendly cleaning.

Dry ice cleaning of electronic component molds: without dismantling the mold, directly heat-clean the mold; clean thoroughly, improve the yield rate, and reduce downtime; quick cleaning does not damage the mold; dry cleaning, no residue.